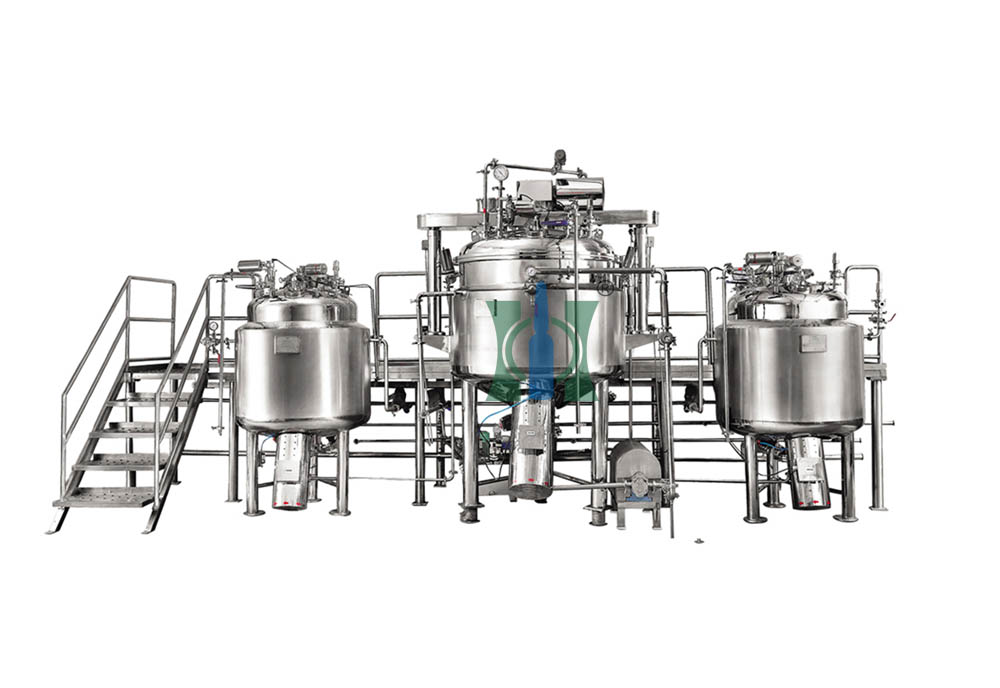

Ointment/Cream/Lotion Manufacturing Plants

Ointment manufacturing plants are facilities designed for the production of pharmaceutical ointments, creams, and other topical products. These plants play a crucial role in the pharmaceutical industry by producing a wide range of medicated and cosmetic creams that are applied externally to the skin. Ointments are semi-solid preparations typically consisting of a combination of active pharmaceutical ingredients (APIs) and various excipients (inactive ingredients) that provide the desired texture, stability, and therapeutic effects.

The manufacturing process in ointment plants involves several steps, including:

Weighing and Mixing, Heating and Melting, Homogenization, Cooling, Filling and Packaging,

Quality Control

Type of manufacturing plants:

Ointment manufacturing plant

Cream manufacturing plant

Lotion manufacturing plant

Gel manufacturing plant

Liquid syrup manufacturing plant

Oral liquid manufacturing plant

Ointment manufacturing plant also used as cream manufacturing plant, lotion manufacturing plant, gel manufacturing plant. The similar plant we make for liquid manufacturing plant, liquid syrup manufacturing plant, oral liquid manufacturing plant.

It's important to note that ointment manufacturing plants must adhere to strict regulatory guidelines and Good Manufacturing Practices (GMP) to ensure the safety, efficacy, and quality of the produced products. Regulatory authorities such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) provide guidelines that manufacturers must follow to obtain approval for their products and maintain compliance.

Additionally, ointment manufacturing plants may also produce other topical products such as gels, lotions, and emulsions. These plants require specialized equipment, skilled personnel, and a controlled environment to produce consistent and high-quality products.

The same plants uses for ointments, creams, gel, lotions and emulsions.