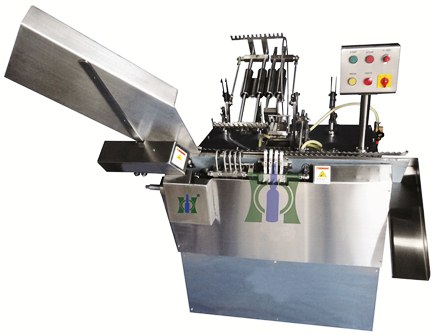

It is best buy for crushable ampoules and biological indicators with the size diameter ranging from 6mm to 15mm and length can be customized anywhere between 55mm to 100mm. Our filling and sealing machines have CE certifications. The entire operation of filling and sealing of onion skin tubes are without human touch to avoid contamination of the precious liquid material. In the absence of Ampoules, machine automatically stops the process and saves electric consumption as well the costly materials being wastage. The main application of this is found in Chemical industries. The production can be significantly increased with the four head filler and sealer to achieve up to 90 tubes per minute. Operational Process:- The indicator ampoule in tray is directly loaded in to SS hopper in machine. Well synced star wheels moves the tubes symmetrically for sequentially pre-gassing, filling, post gassing, pre-heating and sealing.

Features

cGMP model (Off-line).

Compact and vibration free structure.

All Contact parts made from Stainless Steel AISI 316 material.

Other parts (non-contact) made from Stainless Steel AISI 304, Mild Steel, Brass etc.

Stainless Steel AISI 316 Dosing Syringes and Filling Needles..

Single motor synchronized all drives of the unit..

Smooth ampoule rotating unit at the sealing station. Pre & Post nitrogen flushing unit..

Pre Heating unit available for thick glass ampoules.

Flow meters for Nitrogen, LPG and Oxygen gas regulation easier.

No Ampoule No Filling” function avoid consumption of expensive liquids.

Minimum time to change over ampoule size.

Variable frequency drive for regulating machine speed easier through speed pot.

Vertical tray collection unit duly filled and sealed ampoules.

Stainless Steel west tips collector for cutting the glass ampoules tips while sealing.

Suitable for all open mouth glass ampoules.