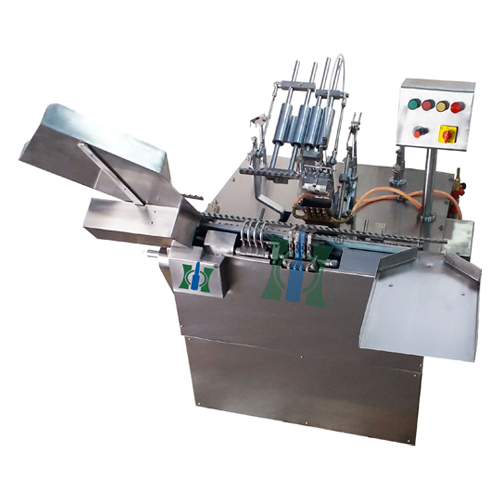

Features Of Four Head Ampoule Filling and Sealing Machine

Compact structure free from vibration.

Contact parts made from Stainless Steel AISI 316L.

Non-contact parts made from Stainless Steel AISI 304, Mild Steel, Brass etc.

Dosing Syringes/pumps and Filling Needles made of Stainless Steel AISI 316.

All drives of the unit synchronized with Single motor.

Pre & Post nitrogen flushing unit.

Smooth ampoule rotating unit at the sealing station.

Pre-Heating unit for thick glass ampoules.

Easy regulation of oxygen, LPG and nitrogen gas with flow meters.

No wastage of expensive liquids with “No Ampoule No Filling” feature.

Easy regulation of speed with variable frequency drive.

Vertical tray collection unit duly filled and sealed ampoules.

VFD drive for easy speed regulating (delta make).

Stainless Steel west tips collector at the bottom side of machine.