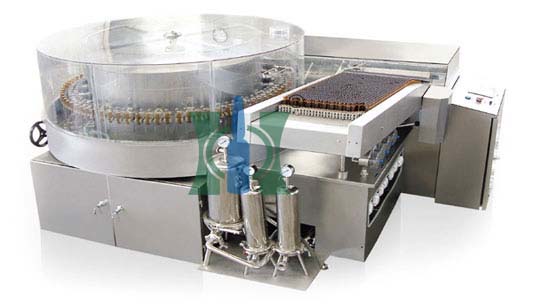

A rotary ampoule washing machine is a specialized pharmaceutical equipment designed to clean and sterilize glass ampoules used for containing injectable liquids or substances. Ampoules are small, sealed containers with narrow necks, commonly used in the pharmaceutical industry to store and preserve medications, vaccines, and other critical substances.

It is suitable for busy pharmaceutical and chemical packaging industries as it has a high production output of 240 ampoules per minute and is able to clean 1ml – 10ml ampoules. Each machine has 6 washing stations, with each station having 3 needles for water cleaning and 3 for air washing. The equipment has three 25 liter tanks and three pumps to hold and pump cleaning agents. It is also equipped with a cassette of grippers at each station to hold and turn the ampoules. The machine has automatic in feed and exit system.

All internal surfaces are manufactured from stainless steel to prevent corrosion while the rests are manufactured from plastics. The fabrication and materials are made to according cGMP standards and quality is guaranteed.

A rotary ampoule washing machine is a specialized pharmaceutical equipment designed to clean and sterilize glass ampoules used for containing injectable liquids or substances. Ampoules are small, sealed containers with narrow necks, commonly used in the pharmaceutical industry to store and preserve medications, vaccines, and other critical substances.

It is suitable for busy pharmaceutical and chemical packaging industries as it has a high production output of 240 ampoules per minute and is able to clean 1ml – 10ml ampoules. Each machine has 6 washing stations, with each station having 3 needles for water cleaning and 3 for air washing. The equipment has three 25 liter tanks and three pumps to hold and pump cleaning agents. It is also equipped with a cassette of grippers at each station to hold and turn the ampoules. The machine has automatic in feed and exit system.

All internal surfaces are manufactured from stainless steel to prevent corrosion while the rests are manufactured from plastics. The fabrication and materials are made to according cGMP standards and quality is guaranteed.

Features:

Rotary mechanism.

Complete cGMP Model

Higher production output capacity of 120 &240 Ampoules per Minute

All contact parts with the internal surface of Container and the wash media are made from AISI 316L Stainless Steel.

Other parts are made from engineering plastic, FDA approved or AISI SS 304 Stainless Steel.

All finishes, welding joints are processed, treated & equipment selected in accordance with cGMP standards.

Machine provides 3 water washes & 3 Air washes.

Complete flexibility with user for washing cycle.

Suitable for 1ml to 10ml Glass Ampoules.

Washing sequence can be made as per customer’s requirements.

3 Pumps and 3 Tanks of 25 liters each.

Each washing zone with independent circuit to avoid contamination.

In feed and Exit of containers